origin: rwanda

posted: august 2015

it took far too long to post a blog about what might be the most exciting thing we’ve done since starting white label: our field trip to rwanda. because writing a full-blown report has proven to be close to impossible - we are currently working on ways to upgrade our blog production - we decided to post the series of photos which appeared earlier on instagram, with a few additions between the lines. the story of our trip follows the processing steps the coffee cherry travels through in the countries of origin. that way we can show the incredible amount of eyes, hands and machines that coffee meets before being exported.

but, before we dive into the country of a thousand hills, we want to start by thanking once again mr. lennart clerkx - the founder of the new school coffee trading company this side up - for putting his vision into practice by taking us under his wings. we love you man.

and now quickly off to magical rwanda, enjoy.

it all starts high up in the rwandan mountains, where the coffee cherries tan from green to deep red.

the red cherries are harvested by hand, one by one. next, they are collected (by the cooperative) and brought to the washing station for processing.

note: in rwanda, all coffee is processed ‘washed’, which means the coffee beans are removed from the cherry using water. in other countries coffee can also be processed using the ‘natural’ way. then, the coffee cherry is fully dried in the sun until one is able to remove the coffee beans. both processing methods have its advantages and effect on a coffee’s flavour profile. for now, we’ll continue with the washing in rwanda.

at the washing station, the first step in removing the green coffee beans from the cherry is running it through a pulping machine (of which this photo shows a close up). during pulping the skin of the cherry and part of the mucilage is removed.

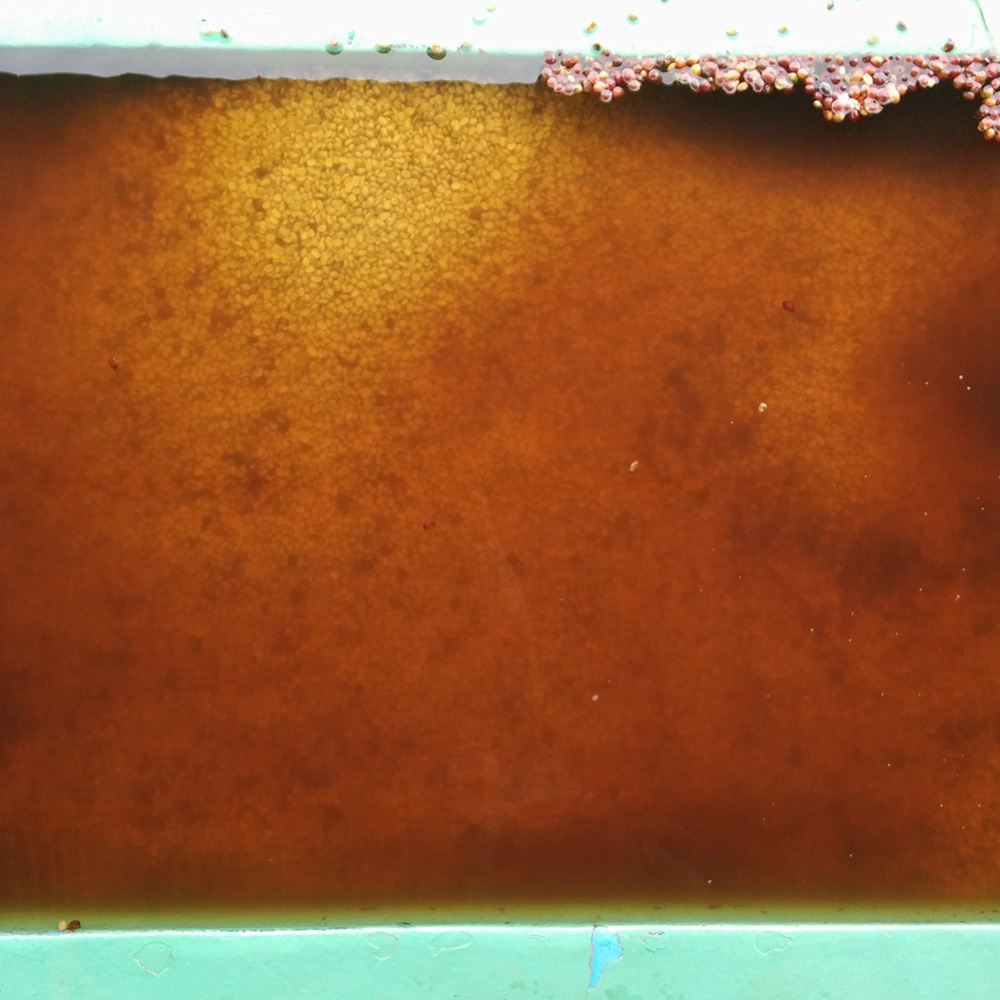

after pulping, the coffee beans are transferred to fermentation tanks. there, the coffee beans ferment 12-36 hours in order to remove the remaining mucilage. any floating beans are marked as defects and discarded.

after the fermentation tanks (to the right on the picture), the coffee beans (still in parchment and mucilage) are released onto this water slide for the actual washing. here, using running water, the last of the mucilage is scrubbed off the parchment using a kind of broom. in the end, the heavier (higher quality) beans will end up higher on the slide while the lighter (lower quality) beans will end up at the end.

after all the washing, the green beans (still safely inside their parchment) are laid to dry in the sun using these raised drying beds until the green coffee beans will reach the desired moisture level (around 12-13%).

while the coffee is on the drying beds, farmers will search for (color) defects and remove accordingly.

and in case of upcoming rain like on this photo, all beds will be covered to make sure the process is not disrupted.

and while the cherries are drying, the first of many selection processes begin by sorting out faulty - brown and black colored - beans by eye and hand. here at the coko washing station, which is the name giver of our rwandan coffee.

note: the coko washing station is the name giver of our coffee because in rwanda you do not find large scale farms. in general, small scale farmers who supply themselves and the local market also grow some coffee for the export as a little extra. therefore, in rwanda - and other coffee producing african countries like ethiopia or kenya - the washing station, which is usually connected to a cooperative, is the most precise way of describing a coffee’s origin.

after the drying at the washing station, the green coffee beans - still inside the parchment - are bagged and transferred from the lush country side to the rwandan capital kigali for further processing at a dry mill.

a dry mill is a much larger and more industrial place than the washing station (which is also referred to as 'wet mill'). there - first off - the parchment is removed by a 'huller': a machine that shakes the green beans so hard that the dried parchment is crushed and - finally - the green coffee bean is set free!

now that the green beans have been freed from the parchment, they are exposed to all kinds of quality assessments, like the gravity table on this picture.

the gravity table constantly bounces the green beans, and therefore, the heavier (higher quality) beans are moved upwards while the lighter beans stay on the lower side of the table.

also, screens that assess the size of the bean (larger beans are usually of higher quality) are used as are color sorting machines that detect defected, faulty colored beans.

but machines are not able to filter out all the faulty beans. so a lot of people make a big contribution by spotting defected beans by eye and manually removing them.

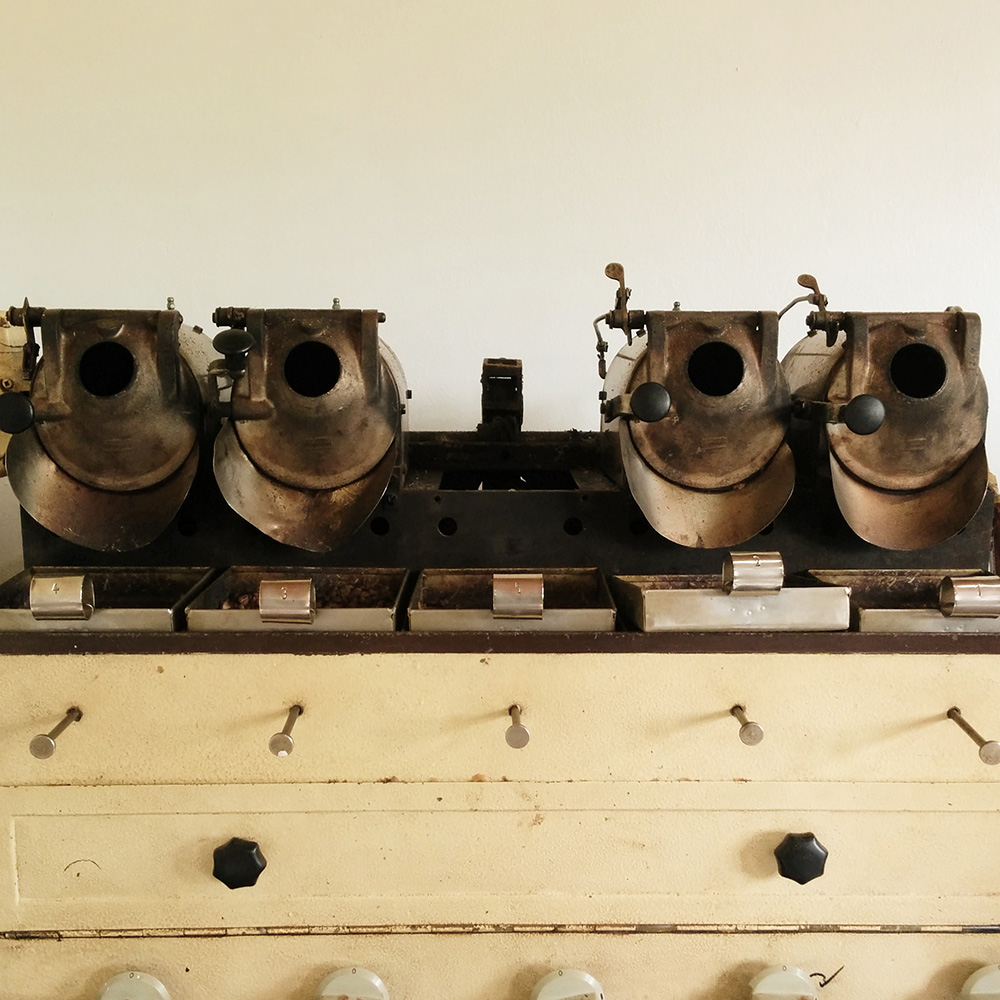

besides all the manual and mechanical checks of the green coffee beans, a lot of tasting is done to assess and improve coffee quality in rwanda. and we were very impressed with the level at which this is done. the equipment we spotted was also very state of the art, but we just had to share this photo of a classic sample roaster at NAEB (the national agricultural export development board) for it is so beautiful (and also still works like a charm).

we also joined a couple of cuppings and got very excited about this year's harvest. and with the focus of the rwandan coffee professionals, we can only expect the rwandan coffee to make big improvements every year.

so, we surely can't wait for the next bags from the coko washing station to arrive, such a long time till october...!

and on our parting shot, we see mr lennart clerkx from @thissideupcoffee checking up on some jute bags, ready to be exported. had such a good trip, clearly, business and pleasure do go together. <3

in closing, we like to note that we initially choose the coko coffee for its beautiful aroma. after our trip, we decided to carry this coffee year round, because the whole story - the flavour, the people involved and the value chain - fits for us with this coffee. this is how we like to work, so never a day without coko at white label.